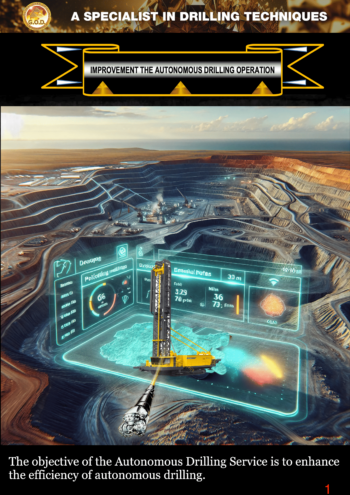

Global over drilling

IMPROVING DRILLING KNOWLEDGE IN LATIN AMERICA

- Our drilling training programs are based on developing people’s competencies and optimizing the drilling process.

- The objective of our training program is to improve technical knowledge and optimize the resources provided by the company. We have proven that when we dedicate more time to enhancing the competencies of drilling operators and supervisors, mine productivity increases, the availability of the drilling fleet improves, operational risks decrease, and—most importantly—total drilling costs are significantly reduced, leading to substantial financial savings.

- At the beginning of the process, we conduct an evaluation on operators and supervisors to identify skill gaps and assess their technical knowledge before the training. This evaluation establishes a baseline to ensure our training effectiveness and improve current KPIs.

- Using this methodology, we develop the competencies of each participant attending Global Over Drilling’s training programs.

- We are committed to our key clients in Latin America, supporting the development of their drilling processes and enriching the knowledge of their operators and supervisors. This is how G.O.D. empowers your company, adds value to your drilling operations, and ensures a return on investment in drilling training.

Global over drilling

INDICATORS OF OUR SERVICES (KPIs)

- Improve operational safety and reliability during drilling.

- Increase the physical and operational availability of the drilling rigs.

- Enhance the ability to drill in challenging areas of the mine, such as refill, crests, and fractured zones.

- Adjust operational parameters for optimal performance for each type of formation.

- Modulate the air compressors of the drilling fleet.

- Reduce the number of short, deviated, or collapsed holes.

- Reduce operational delays.

8. Reduce erosion at the hole collar.

9. Improve hole quality to reduce the amount of explosives used.

10. Improve drilling velocity.

11. Enhance the performance of tricone bits, drill bits, and drill rods.

12. Ensure the correct selection of tricone bits based on the lithology of the mine.

Benefits of G.O.D. Drilling Services

G.O.D. Services

Training

G.O.D. Services

- Reduction of operational drilling risks.

- Increase in the competence of operators and supervisors.

- Reduction of total drilling costs.

- Increase in drilling speed.

- Increase in the availability of drilling rigs.

- IADC configuration in autonomous drilling rigs.

- Extended life of drill components.

- Increase in the productivity of the drilling fleet.

- Adjustment of the operational parameters of the drilling rigs.

- Improvement in subdrilling.

- Selection between rotary drilling and rotary-percussive (DTH) drilling methods.

- Improved drilling rig maintenance scheduling.

Training

- Enhancement of the competence of your drillers and mine supervisors.

- Reduction of operational drilling risks.

- Reduction of total drilling costs.

- Increase in the availability of drilling rigs.

- Extended life of drill components.

- Increase in drilling speed.

Our

Offices

CHILE

-

Av. Presidente Kennedy #5600, Of. 509, Vitacura, Santiago de Chile

CP: 7650724 - Casa Matriz - galcala@drillingod.com

- +56 987 29 79 89

MÉXICO

-

Colina, #136, Colonia Portal de Las Lomas,

Saltillo Coahuila. - galcala@drillingod.com

- (+52) 844 418 00 65

PERÚ

- Av. EEUU Conjunto habitacional el correjidor 1 A Depto 303, Arequipa.

- galcala@drillingod.com

- +569 8729 7989

BRASIL

- Avenida JK #147 Barrio Centro Canaa do Carajas PA Brasil

- galcala@drillingod.com

- (+55) 94 9191 2847